Clothes made from natural materials have always been popular. The secret to success lies in unrivaled softness and attractive appearance. Before specifying how to sew a suit from knitwear, you need to learn about the features and types of fabric. After that, you can prepare the tools, take measurements, create patterns and sew the parts.

Peculiarities of working with knitwear

The process of sewing knitwear does not present any particular difficulties. The versatility of the material allows you to create almost any items from it: from luxurious evening dresses to beautiful underwear. The fabric has many varieties. The following types are suitable for making a knitted suit:

- Cotton footer. Delicate, unpretentious knitwear, designed for sewing light summer clothes. Advantages: hygiene, breathability, wear resistance. The fabric holds its shape well, is environmentally friendly, does not require complex care. Disadvantages: deforms under high temperatures, loses its original appearance under direct sunlight.

- Viscose. Light, soft fabric, pleasant to the touch, suitable for sewing summer clothes. For durability, it is supplemented with artificial fibers. Advantages: it lets air through, does not electrify, does not become covered with pellets, provides full heat exchange, retains color well, does not fade. Disadvantages: it requires special care, wrinkles, fades in the sun, deforms when wet.

- Jersey. The structure of this type of knitwear consists of interwoven loops, connected columns and rows. It has high elasticity and flexibility, suitable for sewing clothes for the off-season. Advantages: softness, tendency to stretch, holds shape well, wear resistance, breathability. Disadvantages: deforms when exposed to high temperatures, takes a long time to dry.

- French knitwear. Made from textured synthetic fibers. Characterized by high stretchability, keeps its original shape for a long time, suitable for sewing clothes for the off-season period. Advantages of French knitwear: elasticity, durability, color retention, many varieties, versatility, antistatic properties. Minus - tight fit of the body, in which all the flaws of the figure become more pronounced.

- Biflex. Artificial stretch knitwear has high elasticity and stretches in different directions. Fabrics with lycra in the composition are used to produce tight-fitting clothing models. Advantages of knitwear: durability, wear resistance, dries quickly, is easy to wash, does not fade in the sun, does not require ironing, does not restrict movement. Disadvantages: accumulates static electricity, fibers shrink when exposed to high temperatures, poorly permeable to air. Stretch knitwear is suitable only for those with an ideal figure, as it can emphasize existing flaws.

- Cashmere knitwear. Warm, soft material, used to create winter items. Advantages: light, thin, low thermal conductivity, durability. Disadvantages: absorbs odors, expensive.

- Wool knitwear. It is comfortable, has an attractive appearance, and is used to sew warm clothes, in particular suits. Advantages: high thermal conductivity and air permeability, moisture removal from the body, resistance to abrasion, light, elasticity. Disadvantage: requires delicate handling.

- Fleece. Artificial fabric made of polyester fibers, suitable for the winter season. The advantages of this knitwear: hygiene, thermoregulation, elasticity, durability, lightness, moisture removal, affordable price. Disadvantages: accumulates static electricity, is prone to ignition, requires frequent washing.

- Fukra. The main feature of the fabric is that the upper side of the canvas is matte, the lower side is glossy and smooth. The material is suitable for creating warm things. Advantages: durability, easy care, resistance to deformation, spectacular appearance. Disadvantages: tendency to accumulate static electricity, lack of hygroscopicity and air permeability.

- Velour. Velvety knitwear with a fleecy surface, soft and dense. Designed for wearing in cold weather. Advantages: does not wrinkle, retains heat, pleasant tactile sensations. Disadvantages: susceptible to abrasion, creases, collects dust, wool, threads.

Among the features of knitwear are its high plasticity and stretchability. That is why the patterns are applicable to several sizes at once, up to 5. Before starting work, cotton jersey must be washed, thoroughly dried and ironed. Only after this can you begin cutting out the suit.

When working with knitwear, minor inaccuracies in sizes are acceptable. The stitches are of great importance, so before sewing a suit, you should decide on the stitch size, select the optimal needle, and then practice on a small piece of fabric.

Materials and tools

Before starting work, you need to prepare all the necessary tools. To create a knitted suit you will need:

- patterns;

- scissors;

- threads;

- soap;

- rubber;

- measuring tape;

- suitable fabric;

- decorative elements to taste.

To make a quality knitted suit, it is not enough to have one sewing machine. It is advisable to use a chain stitch device in your work. The equipment allows you to make the reverse sides of the seams smooth. An overlock is indispensable when sewing suits from stretchy thin materials, it quickly makes a zigzag. The finished seams are elastic, have no tightening or missed stitches.

It is necessary to replace the needles on the machine. Products with rounded ends that will pass between the fibers without damaging them are suitable. There are tools designed specifically for a certain type of material: jersey - for wool and cotton knitwear, stretch - for synthetics or fabrics with lycra in the composition.

Stages of sewing a tracksuit yourself

To make a knitted suit with your own hands, you need to perform several steps:

- Taking measurements.

- Creating a pattern.

- Cutting out all the elements on the canvas.

- Completing the process by grinding the parts together.

Each step is performed according to the description. This is especially important for beginner seamstresses.

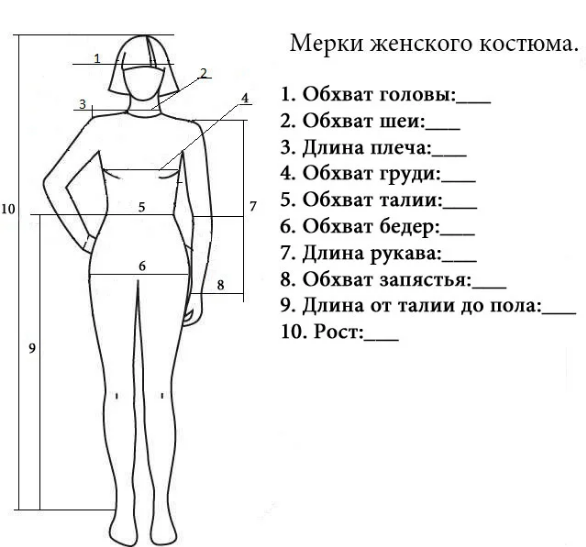

Measures

To make a tracksuit with knitted trousers, you will need to measure all the parameters of the figure. For trousers, the following are determined:

- leg length;

- waist circumference;

- buttocks.

If a tight-fitting model is assumed, you will need to measure the ankle and knee circumference. To make a sweater, the length of the arms, back, shoulders, waist and chest circumference are specified. When creating tight-fitting knitwear, the elbow and wrist circumference is determined. Measurements are taken using a measuring tape.

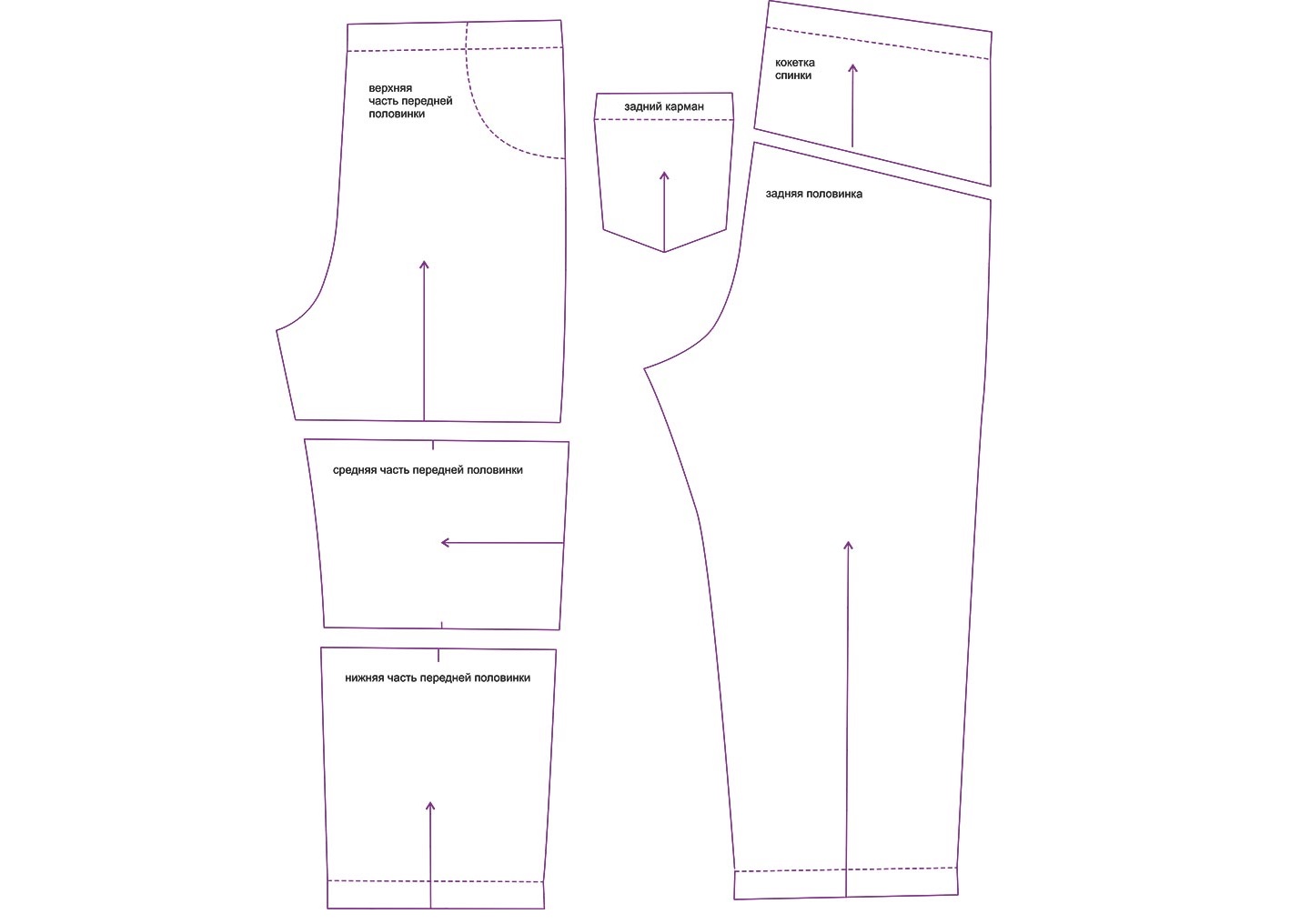

Building a Basic Pattern

For the sweater and pants, you will need to make two patterns. You can use ready-made options or create your own pattern. In the work, you need to use individual parameters so that the product corresponds to the desired size.

The pattern for making trousers consists of two elements: front and back. If a loose item is planned, another 3 to 5 cm is added to the measured parameters. For tight-fitting models, the allowance is reduced to 1-2 cm. The back should be wider than the front by several centimeters, taking into account the structure of the hips. The optimal length of trousers is to the ankle or slightly below.

When creating a pattern from knitwear, it is not recommended to make a large allowance, since the fabric stretches well.

The jacket is made in the form of a sweatshirt with a hood with or without a fastener. The top of the knitted suit consists of several elements, for each of which a separate pattern is created:

- Back and front. Both patterns are shortened by the width of the belt minus the parameters of the overlap. The neckline is deepened by 1 cm at the back, by 2 cm at the front, and an expansion of 1.5 cm is made along the shoulder line. The area where the zipper and kangaroo pocket will be located is marked.

- Sleeves. The detail is drawn in a spread, the cut lines at the armhole and at the bottom are aligned. A cuff of 6 cm width is marked. This element usually narrows downwards, but due to the elasticity of the material, such a feature is not taken into account in the pattern.

- Hood. From the main line, 8 cm are measured down, 33 cm up. From the obtained points, horizontals are drawn to the left side. From the starting point, 0.7 cm are moved to the left from the end side of the segment that determines the height of the entire element.

When forming the pattern of the front part, the bust circumference is taken into account, so the shelf will be slightly larger than the back. If desired, a cutout is made, and decor in the form of locks, lacing or patch pockets is placed on the knitted product.For a summer suit, a sweatshirt can be replaced with a simple T-shirt, sleeveless jacket or top.

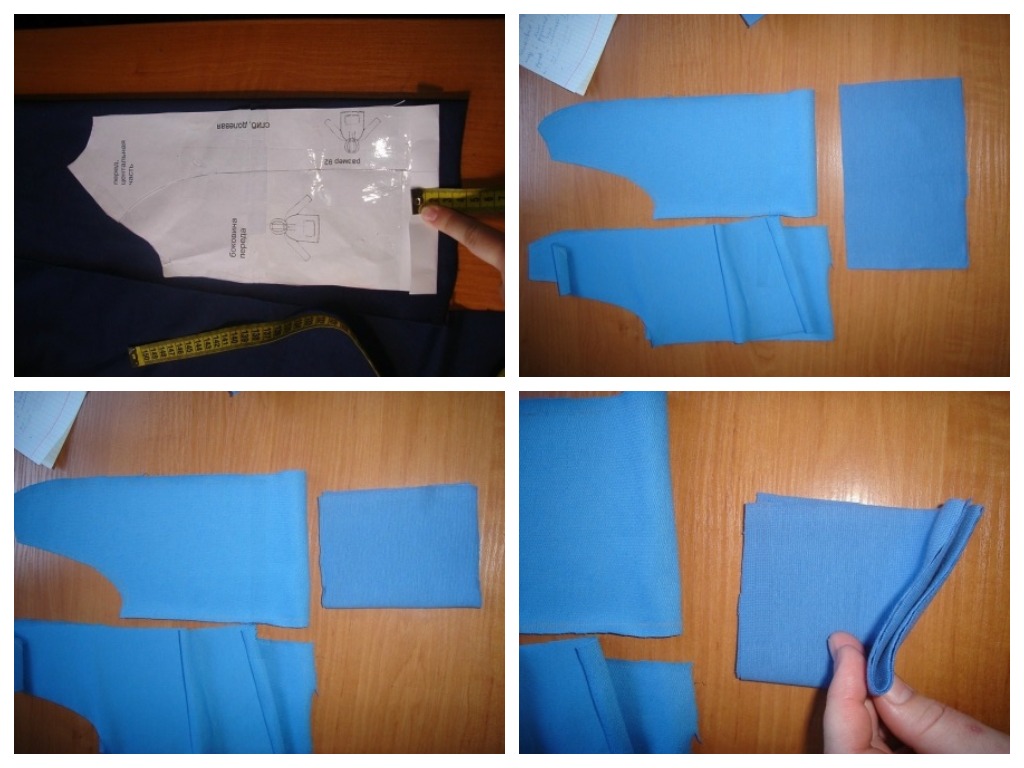

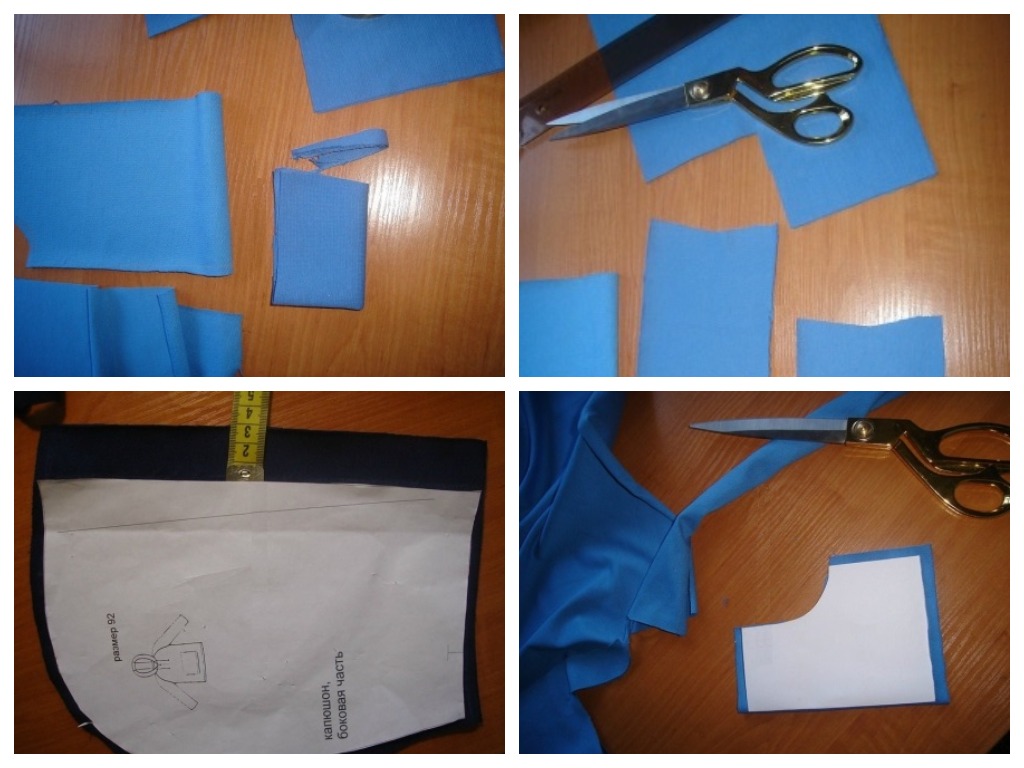

Opening

The patterns are laid out on the surface of the knitwear, taking into account that the direction of the grain line and the loop columns must match. Paired elements and parts located in the same plane should be placed so that their edges look in the same direction. Due to the structural interweaving of the threads, the knitwear can change its shade from matte to glossy and vice versa if the material is placed at different angles.

For thin fabric it is not recommended to use pins. The chalk will not be noticeable on a glossy surface. It can be replaced with disappearing markers, the trace of which will completely disappear after 12-48 hours. You can use tape to fix the paper pattern, then tracing will not be required.

Slippery knitwear must not be cut in two layers.

Stitching the parts together

Before sewing a suit from knitwear, all elements are cut out according to the patterns. Stitching is carried out in the following order:

- The trousers' parts are being sewn together.

- Pockets are inserted into the side seams of the trousers.

- The top is folded over and sewn on, and an elastic band is inserted inside.

- The front and back panels of the jacket are connected to each other.

- A hood is sewn into the neck and there are pockets on the sides.

- The elastic cuff is fixed along the edge of the sleeves.

The product is sewn using a special machine for knitwear. The equipment creates a neat braided seam. A four-thread overlock will also work.

If the knitwear is very wavy when sewing, it is necessary to put paper on the surface or starch the seams. This reduces the material slippage and ensures a smooth connection. Another popular method is to use water-soluble film Avalon.

Sewing a suit model with a narrow skirt

A simple knitted suit consists of a blouse without fastenings and a pencil skirt with a slit. You can use ready-made patterns taking into account individual parameters. All actions are carried out in accordance with the step-by-step master class on making a knitted suit:

- We sew a blouse. The elements are cut out of the fabric: the front part, the back, both sleeves and two pieces for the neckline facing.

- The bust darts are joined and ironed. The shoulder seams are stitched from the inside.

- The back and front are carefully straightened out, and the sleeve is inserted into the specially designated armholes.

- The facing elements are reinforced with interlining and connected to each other, sewn to the neckline from the inside.

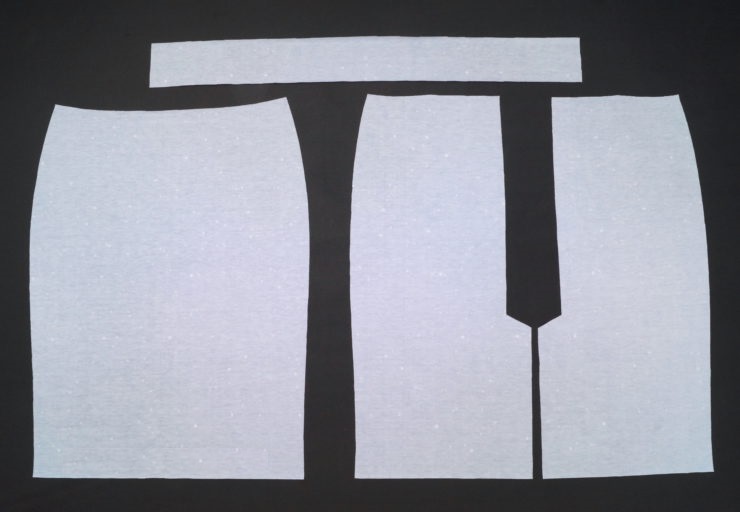

- To make a narrow skirt, all elements are cut out of knitwear.

- Darts are created and ironed, and the areas for the vent and zipper are reinforced.

- The edges of each piece are processed on an overlock. The elements are turned face up, the side seams are stitched, and then ironed.

- For the slit, the areas with the sealant are folded over and stitched.

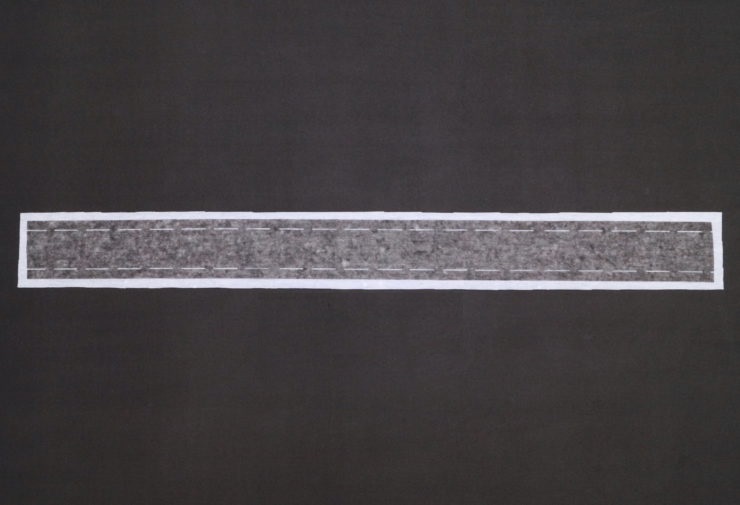

- The area where the belt will be placed is covered with interlining. After that, the strip is bent and ironed to give it an arched shape. After completion, the element is connected to the knitwear.

- A zipper is sewn in. The hem of the knitted skirt is hemmed with a straight stitch to give it an attractive appearance.

Depending on the type and color of knitwear, the suit can be used to create casual and urban looks. An office version can be sewn from dense matte fabrics. Evening wear should be sewn from more elegant materials, for example, velor, French knitwear.

What to do if you don't have an overlock

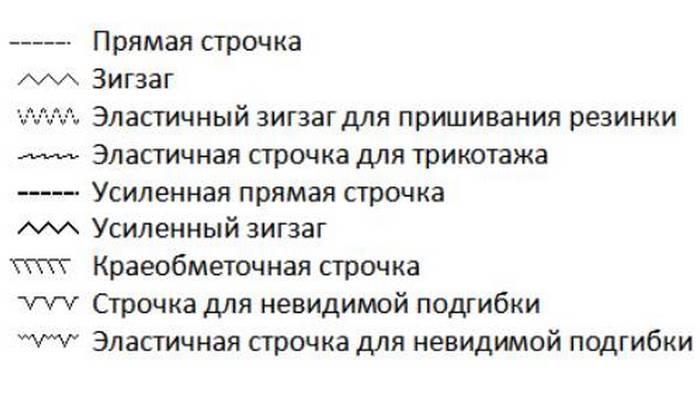

Traditionally, knitwear is processed using an overlock. The equipment is used to stitch edges, which prevents the appearance of creases on the surface of products. If special equipment is not available, it is necessary to use lines that have a high degree of elasticity:

- Straight. Suitable only for weakly stretchy types of material. During the sewing process, you will have to pull the fabric a little towards yourself.

- Zigzag. Used for all types of knitwear, does not tighten the fabric.

- Double. The stitching is done with a pair of straight or zigzag stitches that run at a distance of 3 mm from each other, in parallel.

- Double needle stitch. Found in most modern sewing machines, suitable for all types of material.

- Stretch. Used specifically for sewing knitwear.

To check the elasticity of the seam, it is necessary to pull the elements strongly and determine the area of the rupture. It will be necessary to adjust the tension of the threads to prevent their damage.

Knitted suits can be used to create casual and office looks. They are comfortable for doing sports. Comfortable and elastic knitwear fits nicely to the body, gives comfort, lightness, does not restrict movement. You can update your wardrobe yourself, even novice seamstresses can handle the job.

Video