Natural materials do not lose their value. However, modern models of outerwear require innovative approaches using artificial fibers for better characteristics. One of these materials is bio-fluff, discovered in the 70s of the 20th century. It was developed as a filler and quickly conquered the market due to its unique properties. Bio-fluff is used in outerwear in models of any style for adults and children.

Advantages and disadvantages

The material has a number of advantages over its analogues:

- Bio-fluff in outerwear helps maintain normal temperature conditions in the undergarment space up to 40 degrees below zero;

- Due to its structure, bio-fluff does not penetrate the fabric, maintaining its original shape;

- The filler does not require special care, so items can be washed in a regular machine;

- After washing, the material dries quickly, does not roll or form lumps;

- A special feature of bio-down is its lightness, which allows even bulky items to be practically weightless;

- Synthetic origin makes the insulation hypoallergenic: it does not cause itching or irritation of the skin, and does not absorb foreign odors;

- A high degree of moisture resistance allows it to withstand adverse weather conditions;

- The wear resistance of the material makes products made from it practical to use.

Due to its unique characteristics, the material significantly surpasses its artificial or natural analogues.

Along with the advantages, it is important to know about the disadvantages of the material:

- It can accumulate static electricity;

- Vulnerable to high temperatures;

- Poor moisture drainage requires careful selection of clothing worn under winter clothing;

- The cost of bio-fluff can be significantly higher than similar natural materials.

Knowing the advantages and disadvantages of the filler, you can achieve maximum comfort in using the products.

Methods of obtaining

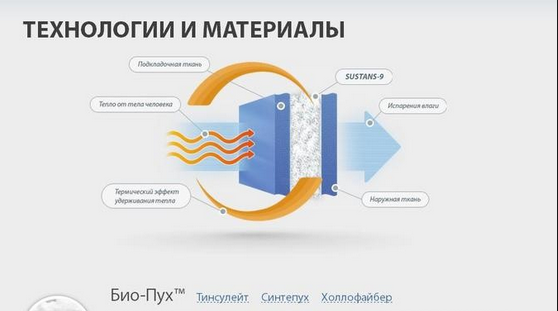

The process of producing bio-fluff consists of several stages:

- The main raw material for the production of the material is Sorona fiber. The finest thread is formed from polyester fibers;

- After which they are twisted into a spiral and acquire a three-dimensional structure, which ensures elasticity and resistance to compression;

- The intermediate blanks are then treated with a thin silicone layer that retains air molecules. This ensures thermal insulation of the filler;

- In some cases, during the production of bio-fluff, additional components (fibers) may be added to the composition to impart special properties:

- Polyethylene styrene;

- Polyolefin;

- Meta-aramid.

The final stage of production is aimed at beating the processed threads together and creating an airy, fluffy mass of white color. Changing the stages of production allows you to create several varieties of material for specific purposes.

Types and their properties

The insulation is used in various areas of the textile industry, and therefore bio-fluff is produced in several types. The marking of samples is usually as follows:

- Group of insulation materials C, which includes several subgroups: C, CS, CDS:

- The special features of category C are the fixation of the insulation on the fabric with glue, which is applied over the entire area every 15 cm;

- Category CS represents synthetic materials on a non-woven base, which is attached using ultrasound;

- The CDS group is a combination of double-sided non-woven base and artificial fluff.

- TIB is a high-volume filler achieved by adding polyolefin fibers to the original raw material. There are several subgroups by density: TIB 100, TIB 120, TIB 200;

- Category P, characterized by shape retention. Such insulation is fixed only in seams, because the surface structure prevents the fibers from shedding. By density, there are: P-100, P-150, P-230;

- Subclass B is a moisture-resistant material that can withstand multiple compressions. The following subgroups are distinguished by density: B 100, B 200, B 400;

- FR class bio-fluff is considered more fire-resistant due to the inclusion of polyethylenestyrene and meta-aramid fibers.

If necessary, the composition of the material can be changed, depending on the purpose of the insulation.

Care instructions

Since the material retains its shape, products made with it do not require special care. Items can be washed by hand or in a washing machine.

However, to increase the service life, it is necessary to adhere to certain care rules:

- It is important to consider what temperature water is used when washing outerwear with bio-down insulation. It should not exceed 40 degrees;

- When spinning, you must select a mode of no more than 600 revolutions;

- Washed items must be dried naturally, away from artificial heat sources;

- When drying, avoid direct sunlight;

- When washing, it is permissible to use fabric softeners;

- Liquid washing powders are considered the best option for detergents, as they do not leave stains;

- When using bulk laundry detergents, it is recommended to use an additional rinse cycle to prevent stains from appearing;

- For effective washing, it is recommended to pre-treat the most soiled areas (around pockets and sides) with laundry soap;

- When washing by hand, do not squeeze the items, as this may cause creases to form;

- After washing, the item must be laid horizontally, and only after the water has drained can it be hung up;

- The item must be ironed with strict adherence to the temperature regime;

- It is prohibited to store products with bio-down insulation in a vacuum bag for a long period of time. Creases may appear on the items.

If all the above recommendations are followed, products with bio-down insulation will last a long time, and their use will provide comfort in inclement weather.

Video