Buyers always prefer things that can be quickly put on and taken off. It is the buttons for clothes that allow you to easily unfasten any sewing products. These fasteners can be invisible or have an original look.

Purpose

A button is a special type of fastener. The fittings are designed to connect individual parts of clothing. The design consists of two elements that fit into each other. Fixation occurs due to the elasticity of a special spring or due to the material of the fastener.

The main advantage of the fastener is the ability to install it on dense materials (tarpaulin, leather). Thanks to the automation of the fastening process, labor productivity and product quality are significantly increased. There is no need to cut materials for loops, and therefore the integrity of the fabric is significantly increased. Among the disadvantages, one can note the not very high strength of the connection of clothing parts and the impossibility of repairing buttons (often they are simply replaced).

Variety of sizes and materials

Manufacturers take into account fashion trends and the possibilities of new technologies. Therefore, fasteners are produced in all possible sizes and variations, made from different materials.

Size range

The most popular and simple are considered to be O-shaped fasteners. Such fittings with a ring fastening are produced with a diameter of 9.5-15 mm (front part). Most often, buttons are used to create workwear or outerwear (down jackets, jackets, coats).

The "Alpha" buttons are distinguished by the presence of an S-shaped contact. This is also a very popular type of fastening. The caps are available in different sizes: large shaped (cap diameter 27-40 mm), with a diameter of 8-25 mm. Moreover, their shape can be very diverse: semicircular or flat, in the form of a droplet, rhombus, square, circle, mesh.

The peculiarity of fastening shirt buttons is the presence of several low spikes (usually 6-8 pieces). Therefore, fasteners are used in the manufacture of light, loose clothing made of knitwear, textiles, and crocheted fabric. Products with diameters from 6.5 to 20 mm are common.

Clamp fasteners (or block fasteners) are distinguished by the presence of a ring fastening on the lid. Common sizes are 8-21 mm.

Material of fittings

To make metal buttons, manufacturers most often use steel with an anodized coating. It should be noted that frequent washing of items causes steel fittings to oxidize over time. Such fasteners acquire an unaesthetic appearance and the level of fixation decreases. Therefore, when sewing expensive items, stainless fasteners made of non-ferrous metals or their alloys are used.

An excellent alternative to metal is plastic. Plastic products are lightweight, are not afraid of moisture, and can have a variety of shades. Although plastic is inferior to metal in terms of strength.

Options for attaching to clothing

In principle, buttons of any type and material perform one function. But to fix the fasteners on things, two types of fastening are used.

Sew-on method

Suitable for installing a fastener consisting of two parts. They are sewn on by hand so that the seams are not visible from the front side of the items. Moreover, the upper element of the button is installed first, and then the lower one. Both metal and plastic products are used to decorate clothing:

- plastic components do not guarantee a strong fixation and therefore are most often used as an auxiliary element. As a rule, they are very popular in the design of children's clothing. They are also attached to the corners of men's shirt collars, to the fastener bars;

- Metal sew-on buttons are used as fasteners for outerwear. For a fashionable wardrobe design, you can cover the buttons with fabric. If you choose a textile of the appropriate shade, the metal fasteners will be invisible on the clothes.

Typically, a section of fabric is reinforced with a lining (non-woven) or the fasteners are fixed to the material folded in half.

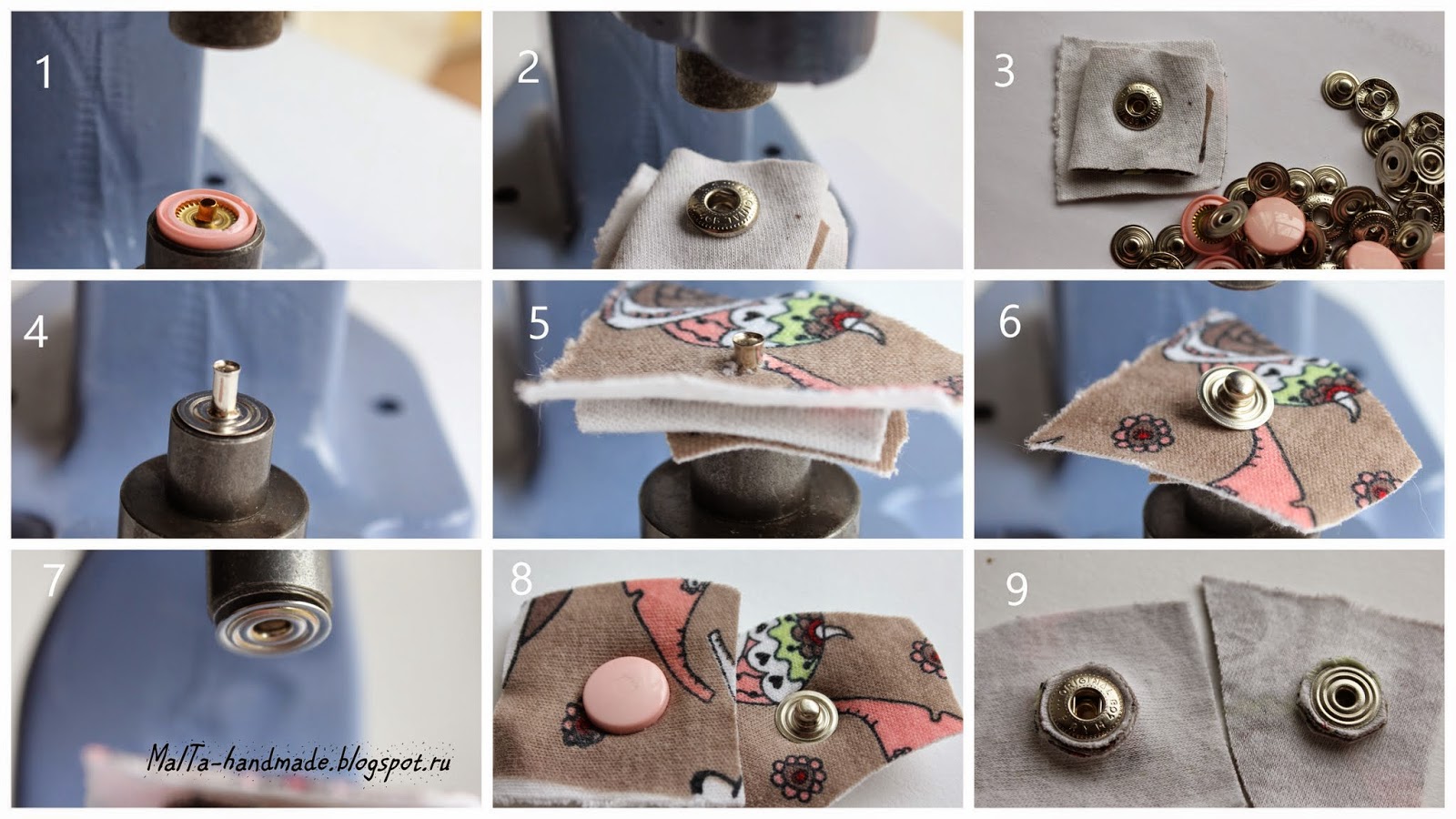

Installing punch buttons

It is widely used in sewing sportswear, outerwear, and denim products. The button set consists of two upper and two lower parts. It is important not to confuse during installation: the "lid" of the fastener is located on the front side of the upper fabric of the item, and the "leg" is on the back. And accordingly, the remaining two elements of the button are placed on the lower field of the garment.

Before installing the fasteners, special holes are first made in the fabric. It is necessary to try to ensure that the diameters of the hole in the material and the button leg match or that the hole is slightly smaller. The parts are secured with a special tool, which can be purchased separately or in a set with the fasteners. The equipment is equipped with a special press matrix and special attachments - punches (of different diameters). At home, when installing buttons, craftsmen use a regular hammer, a Phillips screwdriver or dowel, a wooden block, pliers, and a knitting needle.

Selection criteria

Accessories are an important element of clothing and determine not only the appearance of things, but also comfort and ease of use. When choosing buttons, it is important to consider their characteristics and parameters. It is also necessary to take into account the care features of things, the thickness and quality of the fabric:

- It is advisable to install reliable metal buttons of appropriate sizes on outerwear made of thick fabrics or leather;

- to make it convenient to fasten light jackets, shirts, dresses, you can use original shirt fasteners;

- colorful plastic fittings will perfectly decorate children's clothes. Such buttons will be safe and will help to keep the well-groomed appearance of things even with frequent washing.

Clothes buttons are deservedly very popular with both buyers and clothing manufacturers. This is one of the most common types of fasteners. Thanks to design ideas, buttons have begun to play the role of decoration - hats are decorated with stones, company logos.

Video