With the onset of darkness, the risk of injuries on the roadway increases several times. Reflective tapes for clothing, which perfectly attract attention in conditions of poor visibility, will help reduce them, and sometimes save lives. Using reflective strips is an ideal way to make a road user visible to others.

What is it for?

Reflective tape for clothing is, first of all, a guarantee of safety. Its use increases the visibility of a pedestrian in the dark several times. It is important to understand that if a car is driving with low beams, then a person walking along the side of the road is visible only at a distance of thirty meters. With a reflective strip on clothing, this distance increases several times. In order for the driver to react to an obstacle in time, at least three seconds are needed, during which the car will travel fifty meters. Conclusion - a strip with a reflective effect on clothing helps to focus attention on a person, thereby reducing the risk of an accident.

Reflective tapes for clothing are actively used in various fields of activity. First of all, they are necessary for sewing special clothing for firefighters and emergency workers, sportswear. They are also often used in sewing children's clothes. Tape with a reflective effect is an integral element of the work clothes of utility service specialists, those whose activities take place in conditions of increased danger.

Main characteristics and varieties

When choosing reflective stripes for clothing, you need to pay attention to the following points:

- Type of material - the most common - textile tapes. They can be made of synthetic, natural (cotton) or combined threads. For employees of fire services and structures of the Ministry of Emergency Situations, a special line of reflective elements with fire-resistant impregnations is produced;

- Polyvinyl chloride strips are singled out separately. Their prismatic base increases the coefficient of light reflection and the brightness of the glow in the dark;

- Color - traditionally, a reflective strip of white or gray color is attached to clothing. But in order to increase the ability to reflect light, they are attached to a special fluorescent fabric of bright, acid shades (orange, yellow, green);

- Method of fixation - there are:

- regular tapes that are sewn onto fabric. Strong, reliable fixation of strips requires time, equipment (sewing machine) and certain skills;

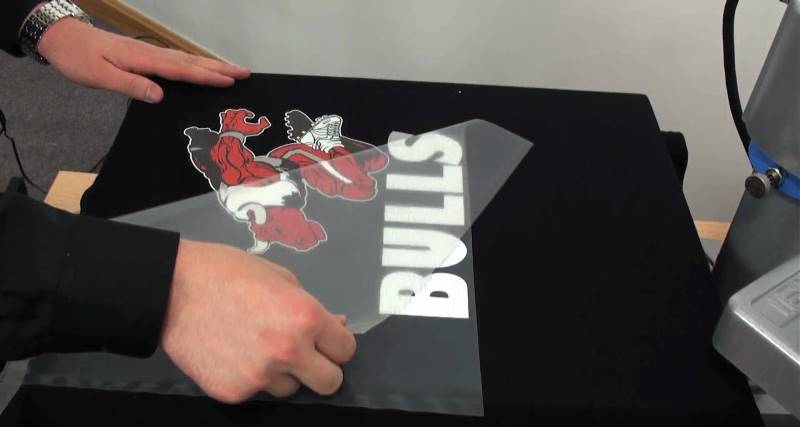

- strips fixed to clothing by thermal transfer. Advantage of use - durability, long service life (withstands frequent washing);

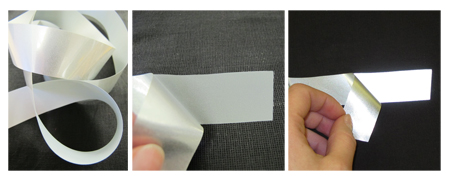

- reflective self-adhesive tapes. Most often used in road construction works. The strip is fixed quickly, does not require special skills, but the self-adhesive base, under the influence of moisture, very quickly loses its strength;

- The width of the strip varies from 12 mm to 50 mm. The widest stripes are used for sewing children's sportswear, tourist equipment (for example, backpacks). A tape 25 mm wide is used for work vests of road service employees, builders, and emergency medical workers.

Main quality indicators of reflective strips:

- strength;

- durability;

- resistance to low temperatures and fire;

- resistance to ultraviolet rays and thermal stress;

- high light reflectivity;

- affordable price.

Correctly selected and fixed reflective tape on clothing will help to avoid injuries, and in some cases save a person’s life in conditions of poor visibility.