Fabric prints are used in industry, advertising, and individual purposes. There are many technologies for applying images: direct printing on clothing, transfer, screen printing, batik. They allow you to get high-quality images, replicate products using fixed shades, or create unique inscriptions. The choice of the optimal method of decorating a material depends on the purpose of use and the type of material.

What is it for?

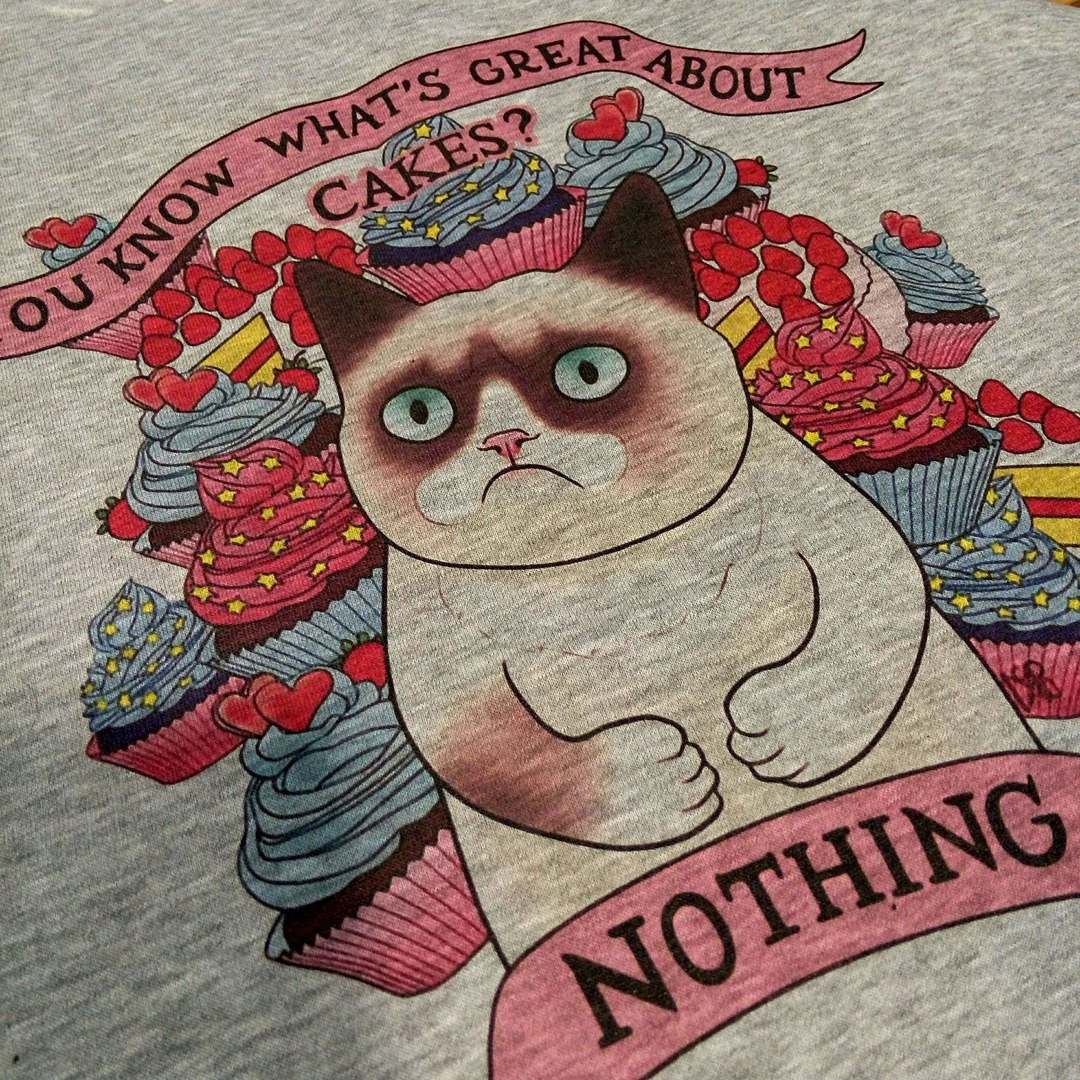

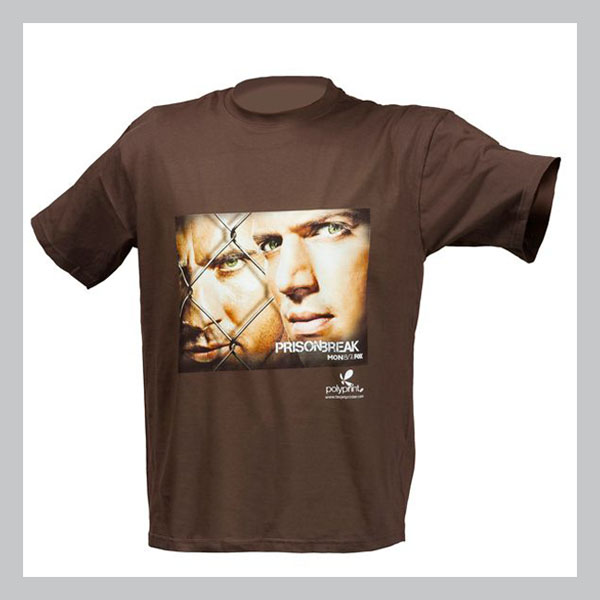

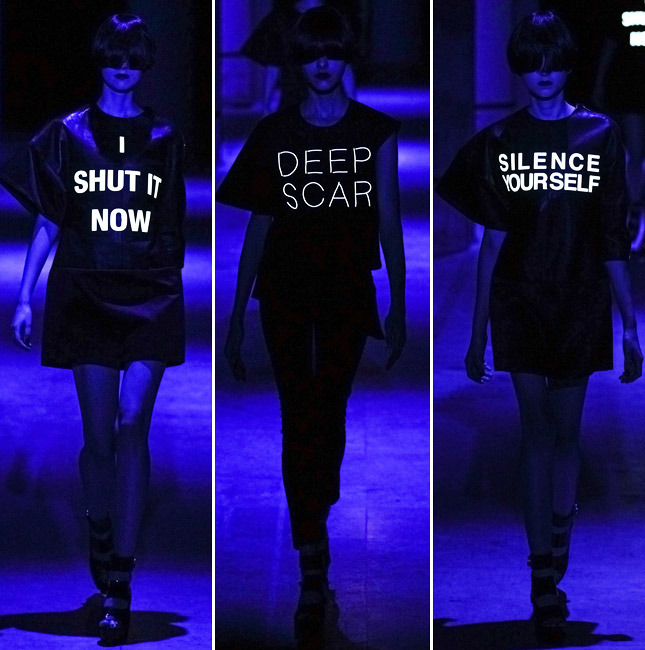

Printing on clothes is a current trend in the fashion world, satisfying the needs of citizens of all categories. The service is inexpensive, which allows everyone to wear stylish things with original designs. Portraits of idols, mottos or funny inscriptions, logos of sports teams reflect the interests of the owners. Many people prefer to create their own print with a photo of a loved one, a pet, a beautiful corner of the world or an interesting inscription. You can draw a sketch yourself or enlist the help of a designer.

A wide group of consumers are companies and enterprises wishing to emphasize the affiliation of employees with a certain company. Clothing made in the colors of the organization and containing the printing of tags, logo, slogan, is of an advertising nature. It attracts the attention of buyers and clients, is perfect for promotional events, product presentations, exhibitions, and other image events.

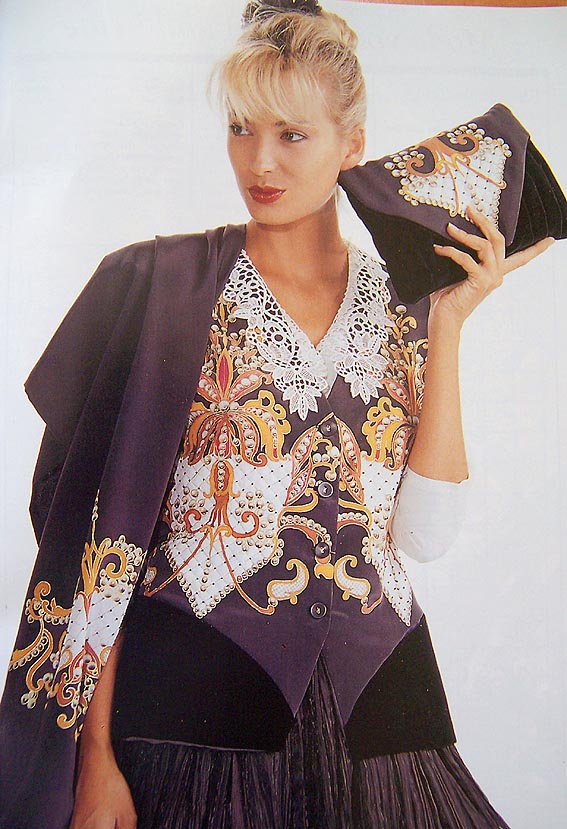

Clothes with exclusive prints are used by music and dance groups, tourist and sports clubs, people who are not indifferent to original designer clothes. Also, things with prints will be a great gift for loved ones, friends or children.

Types and methods of application

The technology of applying prints to clothes was invented in 1950 in Florida by specialists from TropixTogs. Initially, logos of popular resorts, Disney cartoon characters, and photos of athletes were used. Printing techniques were improved, new options for inscriptions and drawings were added, but the most popular remained the direct method of transferring images, batik, and silkscreen printing.

Straight

Digital printing on clothes allows you to get bright, saturated images of any complexity and resolution, relief shapes. The thickness of the paint layer varies in the range of 10-100 microns. It is allowed to use fluorescent and pearlescent paints, special effects (three-dimensional images). Finished products do not fade in the sun, withstand about 50 washes. Among the disadvantages, they highlight the slow speed of applying a pattern to cotton fabric (20 A3 prints per hour). Mixed technology will help to increase the speed of replication: direct printing + transfer.

Transfer

There are two types of printing on clothing: cold peel and hot split – cold and hot peeling respectively. Thermal transfer (hot split) is a technology for transferring images and inscriptions through an intermediate carrier – paper or film, under the influence of temperature and pressure. The result allows you to get a soft sticker, similar to direct screen printing. The paper is removed immediately after pressing. Some of the paint is reprinted onto the fabric, the rest remains on the intermediate carrier. It's easier with film - the picture is cut out on a plotter, placed under a press and that's it! To transfer the image to paper, a printer or paint for white, colored cotton or synthetic fabric, leather coverings is used. Film for printing also comes with smooth and flocked relief.

Cold peeling produces a rubber-like image. The technology provides good covering power, thanks to Superhold Powder or glue covering the plastisol. Cold transfer printing is used to transfer foil that adheres well to the ink adhesive layer.

There are also additional types of transfer printing:

- Reflective images with reflective elements;

- Cold peel plastisol transfer with elastic adhesive layer;

- Flock method of cold peeling with a velvety effect. Printing is done using flocked paper, on top of which a picture is applied with glue. Colored particles (straws, stars, scales, one- and two-color elements, rainbow, mother-of-pearl and metallic) are transferred to the fabric under pressure;

- A cold peel glitter transfer that provides a glossy surface with a metallic effect;

- Sublimation drawings, distinguished by high resolution quality and resistance to external factors. Prints are obtained on polyester fabric under temperature and pressure. During the transfer process, the dye passes into a gaseous state, penetrating the structure of the material.

Transferring an image onto dark fabric requires double use of paint (first the white layer - the base, then the colored paints), which increases the cost of the image printed on black, green, blue clothing.

Silk screen printing

Silk-screen printing is a technology for reproducing inscriptions and pictures (monochrome or color) using a screen printing form. The form material is a thin polyester, nylon or metal mesh with a dense arrangement of threads - 4-400 per 1 cm. The process of transferring the image is carried out with a steel tape that removes the dye from the screen. It passes through the mesh in places where there is no photo emulsion.

Using screen printing technology allows printing more than 50 items per hour with a limited number of shades (1-4). The images are not resistant to washing and ultraviolet light, over time cracks form, the image delaminates.

Batik

There are 3 types of hand-painted batik patterns:

- Cold;

- Hot;

- Free.

Areas that are not to be dyed are covered with resins, beeswax, paraffin. The prepared fabric is dipped in special chemical compounds, the wax is removed and a white pattern is obtained. The artist paints the white background with brushes, treats the clothes with steam. The process is quite labor-intensive, so batik allows you to create individual VIP products from natural silk, cotton, synthetic compounds.

Popular ideas

This year, bright and saturated pictures, black and white images, sepia colors, and negative drawings are in fashion.

Among the women's patterns are:

- Floral combinations of prints in clothing, made in the form of abstractions or one design with many details;

- Anime and cartoon characters that create cute childish images. On the crest of the wave are the heroes of Japanese anime;

- Abstract stripes, zigzags, broken lines. Green, red and blue shades, monochrome are preferred;

- Animal prints – striped or spotted. Eye-catching, extravagant or discreet options, used to combine with everyday clothes.

Representatives of the stronger sex also have favorite options for printing on clothes. The most popular are:

- Photos of football, hockey teams, racers;

- A gentleman's set that includes a tie or suspenders;

- Funny prints for bachelor parties, parties or wedding photo shoots;

- Khaki. Military style T-shirts impress with a variety of camouflage motifs. Men willingly wear the clothes in everyday life, at events, paintball competitions, football matches;

- Funny drawings with humor on military or political topics, there are also jokes of "polite people", caricatures and cartoons of owners;

- Cities, recognizable landmarks of foreign countries. Travelers usually try to take a memorable thing from different parts of the world. Souvenirs are impractical, magnets are not very popular, and a T-shirt or T-shirt will come in handy in everyday life.

Care

Printed materials used on textile fibers are deformed under the influence of chemicals, high temperatures, and sunlight. Items with photo printing have a limited service life, and lose color and shape. However, proper washing, ironing, and storage of clothing help extend the life of the items. Follow simple recommendations for fabric care, depending on the paint application technology.

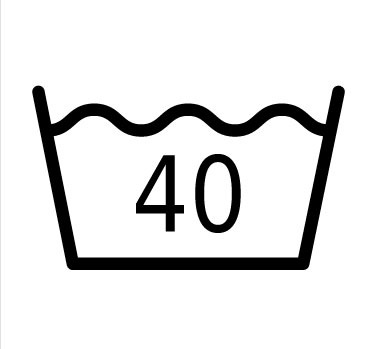

Sublimation

Sublimation on fabric does not require special care. It is enough to provide hand or machine washing at a temperature of up to 40°. Drying takes place in natural conditions at room temperature. Synthetic materials do not wrinkle, which eliminates the need for careful ironing. If the product is slightly wrinkled, it should be turned inside out and ironed around the pattern. The optimal temperature is 60 degrees. A more gentle method is to use a steamer. Use the vertical steam mode, then the pattern and fabric will retain their original properties.

Thermal films (flex, flock)

Care instructions include machine washing of garments inside out at 40°. It is not recommended to use bleaches, dry or iron. Natural drying and steaming are preferred, ironing at medium setting (60 degrees). Avoid direct exposure of the pattern to high temperatures.

Thermal transfer printing requires the following care features:

- Hand wash in cold or warm water (maximum 30-40°);

- No bleach;

- Moderate tumble drying mode, natural drying conditions;

- Iron on reverse side at medium setting.

Direct printing on fabric requires compliance with the following rules:

- Machine or hand wash, turning the product inside out, with water heated to 40°;

- Using liquid detergent instead of powder;

- Neglect of bleach, tumble drying, and exposure of the picture to high temperatures.

Interest in printing prints on clothes is steadily growing, new technologies, design ideas, less expensive but durable consumables are emerging. Choose your option!

Video